Wood Pallets vs. Reusable Pallets: Pros, Cons & True Costs

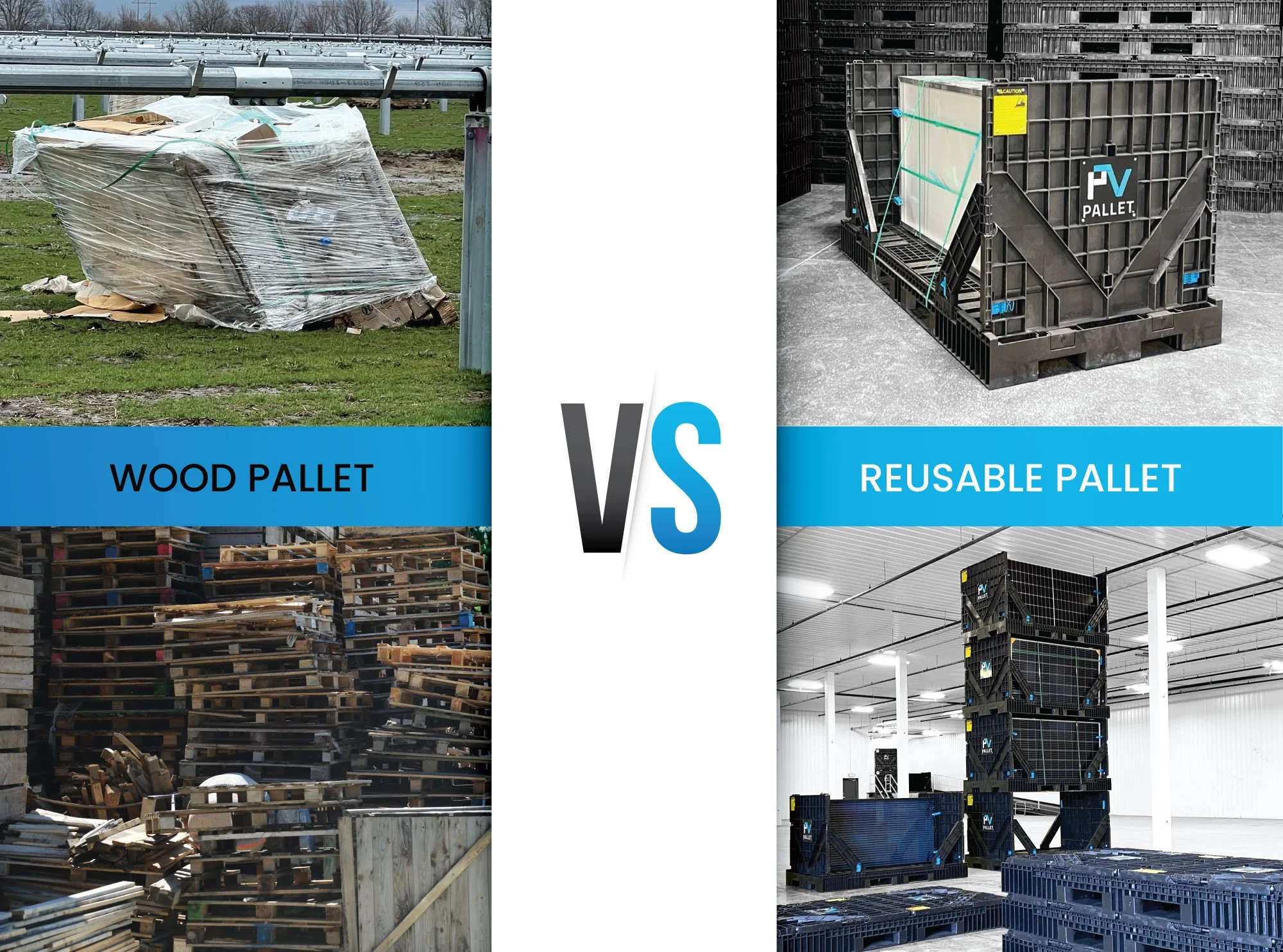

Continued sustainability efforts within the renewable energy industry have led to a vital debate about solar panel packaging: wood pallets vs. reusable plastic pallets. Which option is right for your business?

Wood pallets are the standard when it comes to shipping and storing PV modules. But are they the best solution for your solar business? Installers, distributors, and solar module manufacturers are all considering what approach is best for their operations and their bottom line. From product breakage to packaging CAPEX, there are many factors to consider as you weigh your solar module packaging options.

Wood shipping pallets have been around since the 1920s and were popularized during WWII, when they were used to quickly ship tactical necessities around the globe.[1] Today, thanks to their accessible price point and widespread availability, they are a solar industry staple.

The status quo, however, is not always the most valuable solution for your operations. Should you use wood or reusable pallets to ship and store your solar modules?

Ask these four questions to evaluate what is best for your solar business.

Is your packaging durable?

Partial Load of Solar Modules

Traditional Solar Module Packaging: Cardboad on a Wood Pallet

When it comes to shipping solar modules, wood pallets can threaten the integrity of your expensive cargo. Here are some common frustrations with wood pallets:

Forklift tines easily pierce through the wood, damaging the bottom module(s)

Managing partial loads of solar modules is cumbersome, time consuming, and often result in unnecessary breakage.

Wood pallets decompose in the elements, resulting in breakage and installation delays.

Stacking packaged solar modules adds extra weight on the cargo, resulting in microcracking and breakage.

Wood pallets and broken modules compromise efficiency: for Greentech Renewables, a single broken module could cause an entire day’s jobsite delay for their customer,[2] while Stateline Solar estimated that picking up packaging waste and repalletizing unused modules cost them 624 labor hours each year.[3]

On the other hand, reusable plastic shipping pallets are structurally sound. Their enhanced durability protects delicate solar PV modules in transit—along with your company’s hard-won reputation for delivering on time and on budget.

Your packaging choices impact your ability to deliver on time and on budget.

Is your packaging reliable?

Let’s face it: failing to deliver product safely, efficiently, and pristinely isn’t a good look. That’s why your shipping and packaging choices are a critical part of your business. They communicate that you’re able to do more than just deliver panels—you’ll also deliver on your promises.

Unfortunately, solar module damage is the norm rather than the exception. On average, about 5% of modules shipped on wood pallets are broken in transit. Globally, that’s 21,000,000 broken modules—an industry-wide loss of $5.25 billion in 2021 alone.[4]

Our case studies show a 92 – 100% reduction in breakage when switching from wood pallets to reusable pallets with protective walls.

The last thing companies want is for fragile components in their solar arrays to be damaged during transit. Plastic pallets provide a reliable alternative that helps businesses ensure their shipments reach their destination efficiently and intact. Our case studies show a 92 – 100% reduction in breakage and $29,560 - $96,000 in annual savings when switching from wood pallets to reusable pallets with protective walls.[5], [6]

Your packaging choices impact your company’s reputation.

Is your packaging sustainable?

Sustainability is more than participating in the renewables industry—it’s making intentional choices to help that industry green up. Is your business truly sustainable when it comes to packaging, recycling, and waste?

Most wood pallets are used only once before they wind up in landfills (an estimated 14,000,000 pallets were used by the global solar industry in 2021 alone[7]). At roughly 50 pallets per dumpster load, that’s 280,000 trips from the job site to the landfill each year. When considering that semi-trucks get 6.5 miles per gallon of gas[8] and the average distance to a disposal site is 30 miles, disposing of all those wood pallets uses over 1,200,000 gallons of diesel fuel. Once they arrive at the landfill, the pallets take an estimated 13 years to decompose[9].

Wood pallets also contribute to the 5% breakage rate of modules in transit, resulting in 21,000,000 broken modules each year. Given that only 10% of PV modules are actually recycled,[10] roughly 19,000,000 modules end up in landfills before they even enter service—adding an additional 44,000 truckloads of waste headed to the landfill (and 200,000 gallons of diesel fuel).[11] Some modules are also categorized as toxic waste by the EPA,[12] further contributing to the environmental impact of broken solar modules.

14,000,000 pallets

used to transport solar modules.

19,000,000 modules

end up in landfills prior to installation.

1,400,000 gallons

of fuel to transport pallets & modules to the landfill.

Reusable plastic pallets such as PVpallet Series X generate less waste, prevent product damage, use less energy, promote long-term cost reduction, and contribute to a circular economy.[13] In fact, each PVpallet Series X prevents 230 pounds of plastic from entering landfills (and our oceans). Because they are usable over and over, reusable pallets also reduce carbon emissions by as much as 60%.[14]

Your packaging choices significantly impact the environment.

What is the true cost of your packaging?

The cost of your packaging is more than the initial purchase price—it’s cost plus. Plus disposal fees. Plus company revenue lost to delays at the job site. Plus transportation costs, warehouse rental, product damages, recycling fees, and extra labor.

Wood pallets may seem like a bargain, but their true cost may surprise you. When evaluating the ROI of wood pallets vs. reusable pallets, here are some factors and approximate costs to consider:

Wood pallet: $100 (for installers, this is generally included in the price of the modules)

Dumpster: $200/load of 50 pallets

Waste disposal freight: $2,000/truckload

Solar module replacement, including manhours and lost productivity: $800/module

Broken Module Freight to Landfill/Recycling: $500/MW

Additional weekly labor for site trash pickup: $150

Additional weekly labor to repalletize unused modules: $150

With these numbers, the true cost of wooden pallets for a 1 MW installation is $119,500 (versus the $8300 spent on the pallets). When considering all the costs associated with wood pallets, even “free” pallets would cost $111,200 per MW due to module breakage, waste disposal, recycling fees, and labor inefficiencies.

How much are wood pallets costing your business?

While these numbers can vary from business to business, one thing is clear: the total cost of using wood pallets for solar modules is much higher than just the price of the pallet.

By contrast, plastic pallets like PVpallet Series X can be reused over and over, eliminating replacement and disposal fees. The added structural integrity of a plastic pallet with sidewalls protects modules in transit—reducing breakage by at least 92%[15] [16] (a $92,000 savings per MW in reduced breakage alone[17]). Eliminating the need to dispose of wood waste and broken modules saves another $6700 per MW. Finally, at the end of their usable life, plastic pallets still hold a reclaim value of roughly 10-20% of their original value.

In other words, cost is short game vs. long game. Despite the higher up-front cost for reusable pallets, the lack of recurring CAPEX, disposal and recycling costs, and reduced breakage rate all contribute to a breakeven that typically occurs within 3-5 uses, and a compounding return on investment every use thereafter.

Your packaging choices impact your bottom line.

Wood Pallets or Reusable Pallets?

Ultimately, what matters most is what’s best for your business. In today’s climate-focused and forward-thinking world, what’s best for your business comes down to durability, reliability, sustainability, and cost.

Are you playing the short game or the long game?

Related Articles

[1] Associated Pallets - The History of the Wooden Pallet

[2] PVpallet - Case Study: Greentech Renewables

[3] PVpallet - Case Study: Stateline Solar

[5] PVpallet - Case Study: Stateline Solar

[6] PVpallet - Case Study: Greentech Renewables

[8] Phoenix Truck Driving Institute - All About Semi Truck Fuel Efficiency

[9] PVpallet - Clean Energy's Dirty Secret

[10] Union of Concerned Scientists - Solar Panels Should Be Reused and Recycled. Here’s How.

[11] Green Clean Solar - FAQ: How many panels can fit on a truck?

[12] Environmental Protection Agency - End-of-Life Solar Panels: Regulations and Management

[13] PVpallet - Linear vs Circular Economy

[14] PVpallet - The Future of Sustainability: It’s Time to Think About Your Packaging

[15] PVpallet - Case Study: Stateline Solar